|

|

|

|

Internal standard quantitation

|

|

|

General information

|

Internal standard quantitation uses

peak tables prepared from the standard, similar to the External standard quantitation.

However, a fixed quantity of an additional component is added to

every separation run, including the sample. The peak sizes of the

standards and the sample are then related to the peak size of the internal

standards to compensate for any changes that may have occurred between the

runs.

|

|

|

|

|

General assumption

|

The internal standard technique relies on the assumption that

any changes in the injected amount of the component(s) of interest,

e.g. due to sample preparation losses, correspond to equal changes

in the injected amount of the internal standard component.

|

|

|

|

|

Advantages

|

Internal standard quantitation reduces

errors that are caused by changes in the system between successive

runs with the sample and the standard concentration levels. For

example, there may be unpredictable losses during the sample preparation

procedure or unintentional changes in the amounts that are injected.

|

|

|

|

|

What is a suitable internal standard?

|

A suitable internal

standard must meet the following conditions:

-

It must be well separated

from the components in the sample (not just from the components

of interest).

-

It must not be

present naturally in the sample(s).

-

It must have similar chemical properties to the

component(s) of interest.

To be able to compensate for losses during the sample preparation,

all the standard concentration levels must be subjected to the same

sample preparation procedure as the samples.

Note: If there are

several components of interest, they must all be chemically similar.

|

|

|

|

|

How to perform Internal standard quantitation

|

The

table below describes briefly how Internal

standard quantitation is performed.

|

Step

|

Action

|

|

1

|

Prepare a series of concentration levels from the standard.

|

|

2

|

Add an additional component, the internal standard,

in the same concentration to all the standards and to the sample.

|

|

3

|

Perform a run for each standard and the sample.

|

|

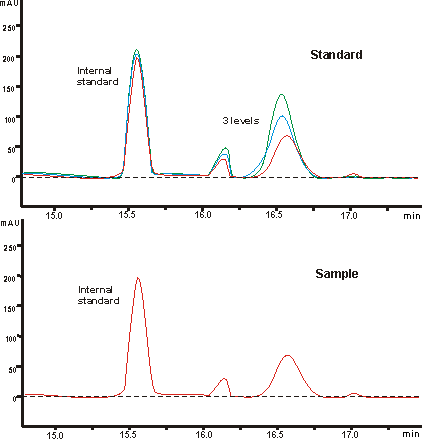

4

|

Integrate the curves to produce a peak table for all

standard runs and for the sample.

Result: Each curve

contains a peak from the internal standard. Changes in the size

of the internal standard peak indicate changes in the system.

See illustration below:

|

|

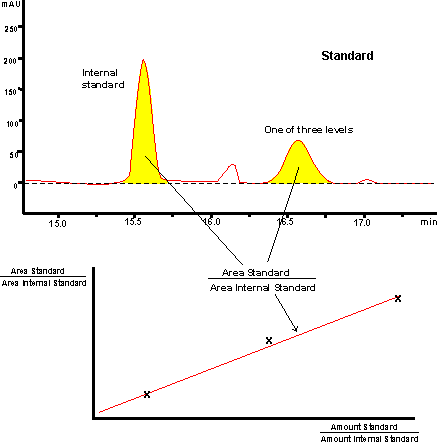

5

|

See illustration below:

|

|

6

|

-

Prepare data

from the sample in the same way as the data from the standard runs

to produce peak sizes relative to the internal standard peak size.

-

The resulting relative value is applied to the calibration

curve to determine the amount and concentration of the component

of interest.

See illustration below:

|

|

|

|

|

|

Reliability

|

Internal standard quantitation

is potentially the most reliable of the quantitation techniques.

However, if the internal standard component is not selected carefully, the

reliability will probably be worse than with the external standard

technique. There are some specific factors that can affect the reliability:

-

There is an increased

risk of overlap when the extra component (the internal standard)

is added if the sample contains many peaks.

-

The addition of the internal standard must be accurate

in both the standards and samples, otherwise, the precision of the

quantitation will be reduced dramatically.

|

|

|

|

2005-06-15

|

|

|